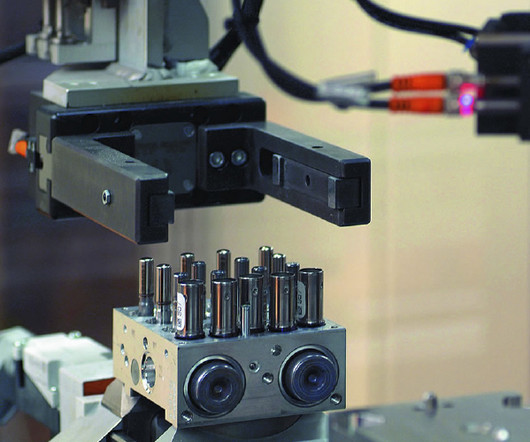

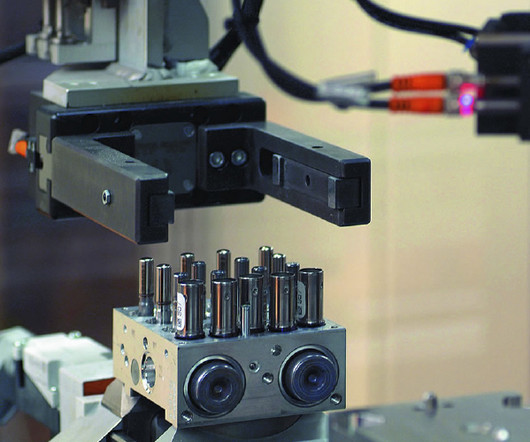

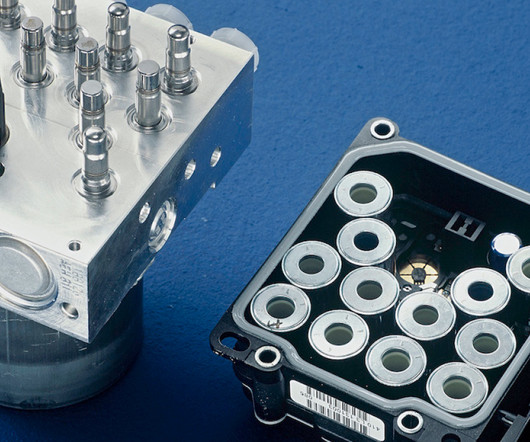

Hydraulic Control Module Diagnostics

Tomorrow's Technician

MARCH 7, 2025

ESC systems add software and sensors like yaw, steering angle and even throttle control to keep the vehicle under control. This will release or bleed off the hydraulic pressure that is holding the wheel. Testing Solenoids Electrically Sometimes a stuck or defective solenoid or pump will set a code. The wheel might start to turn.

Let's personalize your content